Toyota has announced its plans to allocate an additional $2.1 billion toward a battery factory specializing in electric and hybrid vehicles.

The factory is currently being constructed near Greensboro, North Carolina, with the goal of providing batteries to the company’s expansive complex in Georgetown, Kentucky.

The site is significant because it’s where Toyota will produce its inaugural electric vehicle designed for the U.S. market – a spacious SUV equipped with three rows of seats.

Toyota Strengthens Its Commitment to EVs

Toyota, one of the world’s leading automotive manufacturers, has announced a substantial investment of $2.1 billion in its U.S. battery factory expansion plans.

This strategic move reflects Toyota’s commitment to accelerating the development of electric vehicles (EVs) and solidifying its position in the rapidly evolving automotive industry.

Toyota adds $2.1B to its US battery factory expansion plans.

@Toyota will spend an additional $2.1 B to build a new battery plant in North Carolina, the latest sign that the automaker is attempting to catch up with industry that has embraced the move to electric vehicles.

— Entrepren3ur (@Entrepren3ur_io) June 1, 2023

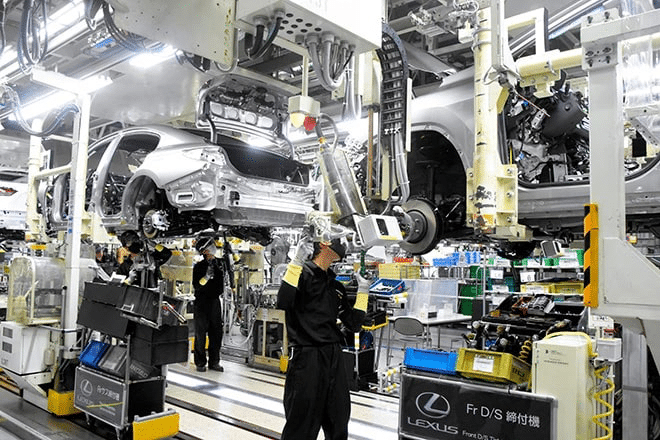

The Japanese car manufacturer also announced that it intends to manufacture its first electric SUV in the United States.

The production will take place at their Kentucky factory and is scheduled to commence in 2025. The forthcoming three-row vehicle will utilize batteries sourced from Toyota’s North Carolina factory.

The battery facility in North Carolina represents the company’s renewed commitment to electric vehicles, although it is not exclusively focused on all-electric vehicles.

When production begins in 2025, only two of the six production lines will be dedicated to all-electric EVs, with the remaining four dedicated to hydrogen-based hybrid EVs.

The investment showcases Toyota’s dedication to sustainable mobility and highlights the importance of the United States as a key market for future EV growth.

As the automotive industry embraces the transition towards electrification, Toyota recognizes the importance of staying competitive in the EV market.

With stricter emissions regulations and rising consumer demand for electric vehicles, automakers are increasingly investing in battery production capabilities.

This recent announcement follows a series of similar moves made by other major automakers looking to secure their position.

Catching Up With Rival EV Makers With New Battery Factory

Toyota has not disclosed the specific gigawatt-hour capacity of the plant.

However, earlier this year, the company announced its intention to launch 10 new electric vehicles, aiming to achieve an annual sales target of 1.5 million EVs by 2026.

Toyota to launch 10 new battery EV models by 2026 Toyota Motor Corp (7203.T) will introduce 10 new battery-powered models and target sales of 1.5 million EVs a year by 2026, aiming for steep growth in a market where it has long been lapped by rivals.

(Note, they are saying… pic.twitter.com/CMmFq4TbZK

— Nicklas 🇸🇪🚗T🐂📈🍀♻️🚀 (@NicklasNilsso14) April 7, 2023

Toyota has faced criticism from investors and environmental groups for its slow adoption of battery-powered cars, resulting in a loss of market share to companies like Tesla.

However, the Japanese automobile manufacturer argues that electric vehicles (EVs) are just one option for customers, and their gasoline-electric hybrids, such as the Prius, Camry and Corolla Hybrid Trim models are a more practical choice for certain markets and drivers.

In his first briefing, Toyota CEO Koji Sato stated that the company intends to expand its offerings in the important EV category in the coming years.

He also emphasized that hybrids will remain an important part of its strategy.

By 2035, it is estimated that over 50% of vehicles produced worldwide will be electric. In order to keep up with this growing demand, it is essential for Toyota to adapt accordingly.

Consequently, the company plans to increase production in the United States, where EV growth surpasses that of the overall market.

During the first quarter report, Toyota experienced a decline in U.S. sales of nearly 9%, while General Motors witnessed an 18% increase, largely due to greater demand for EVs from fleet and commercial customers.

“In the US, where the growth of EVs is outpacing that of the overall market, Toyota’s lack of battery electric models appears to be hurting sales. Toyota reported US sales fell by nearly 9% during the first quarter while GM saw an 18% boost, helped by greater demand for EVs” https://t.co/vL7QBrpGAc

— Simon Evans (@DrSimEvans) April 7, 2023

Recent data from S&P Global Mobility shows that American consumers switching to electric vehicles are largely transitioning from Toyota and Honda Motor Co.

This suggests that there is an increasing awareness that Toyota may be lagging in innovation.

it’s no surprise to see @Toyota solidly in the ‘laggard’ category here.

It has the 2nd to lowest score on ‘strategic vision’ on the electric vehicle transition. https://t.co/3wjSbpzoJP pic.twitter.com/xOJZ13vJCx

— East Peterson-Trujillo (they/them) (@east_p_t) May 31, 2023

According to East Peterson-Trujillo, a clean vehicle campaigner for the nonprofit Public Citizen, Toyota needs to catch up in innovation as the next major leap is already here.

Developing the Economy Through Jobs

The Kentucky complex, which spans 9 million square feet, currently employs 9,500 individuals who work on vehicles such as the Camry sedan, RAV4 Hybrid SUV, engines, and other components.

However, Toyota has announced plans to transition jobs to the new electric vehicle sector.

The company intends to retain 700 full-time jobs through a $591 million investment dedicated to future projects in Scott County.

Kentucky Governor Andy Beshear described this development as a significant announcement that ensures job security for employees at the automaker’s Georgetown complex.

He explained that it would provide reassurance to their families for the foreseeable future.

I’ve got some incredible news! @Toyota’s largest manufacturing operation is going electric, committing to retain 700 full-time jobs through a $591 million investment for future projects in Scott County. Toyota is vital to Kentucky and I am excited for what’s to come. pic.twitter.com/1fFDq3HUtJ

— Governor Andy Beshear (@GovAndyBeshear) May 31, 2023

The increased investment in a U.S. battery factory demonstrates the success of government incentives to promote national battery manufacturing.

The Inflation Reduction Act, enacted in August 2022, includes incentives for domestic battery production.

As a result, several automakers, including Ford, General Motors, BMW, and Hyundai, have committed to establishing and operating production facilities within the United States in the near future.

Related News

- Elon Musk Teases 2 New Tesla EVs, Rumored to Be Cheaper Hatchback and Van

- Rivian Looking at E-Bikes Even as Supply Chain Issues for EVs Drag On

- Chinese EV Stocks Rally as Xpeng Motors Unveils New Production Platform

What's the Best Crypto to Buy Now?

- B2C Listed the Top Rated Cryptocurrencies for 2023

- Get Early Access to Presales & Private Sales

- KYC Verified & Audited, Public Teams

- Most Voted for Tokens on CoinSniper

- Upcoming Listings on Exchanges, NFT Drops