A senior executive at ASML, the largest semiconductor manufacturing equipment maker, told Nikkei that decoupling the chip industry would be “extremely complex and difficult” if not impossible.

This comment isn’t altogether surprising because of the immense complexity of the industry. Semiconductor chips are some of the most complex products in the world and they start as what is essentially sand.

How Semiconductor Chips Are Made

First, an extremely pure silicon ingot is made using sand and complex manufacturing processes. The massive ingot is sliced into incredibly thin sheets called wafers so precisely that they look like mirrors.

The wafers are then oxidized to make them semi-conductive, getting them ready for the next and by far the most complex step: photolithography. The wafer is coated with a substance called a photoresist that reacts with light.

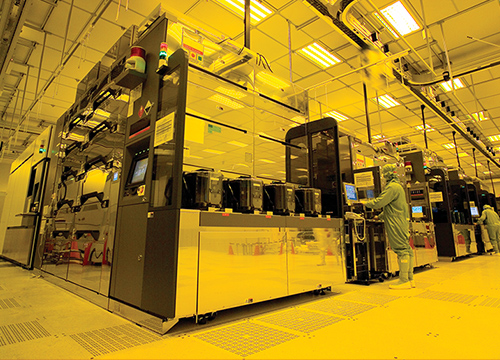

A photolithography machine (probably developed and built by ASML), then selectively shines light in the pattern of the designed circuits. The photoresist hardens when exposed to light, creating what is essentially an outline of the circuit.

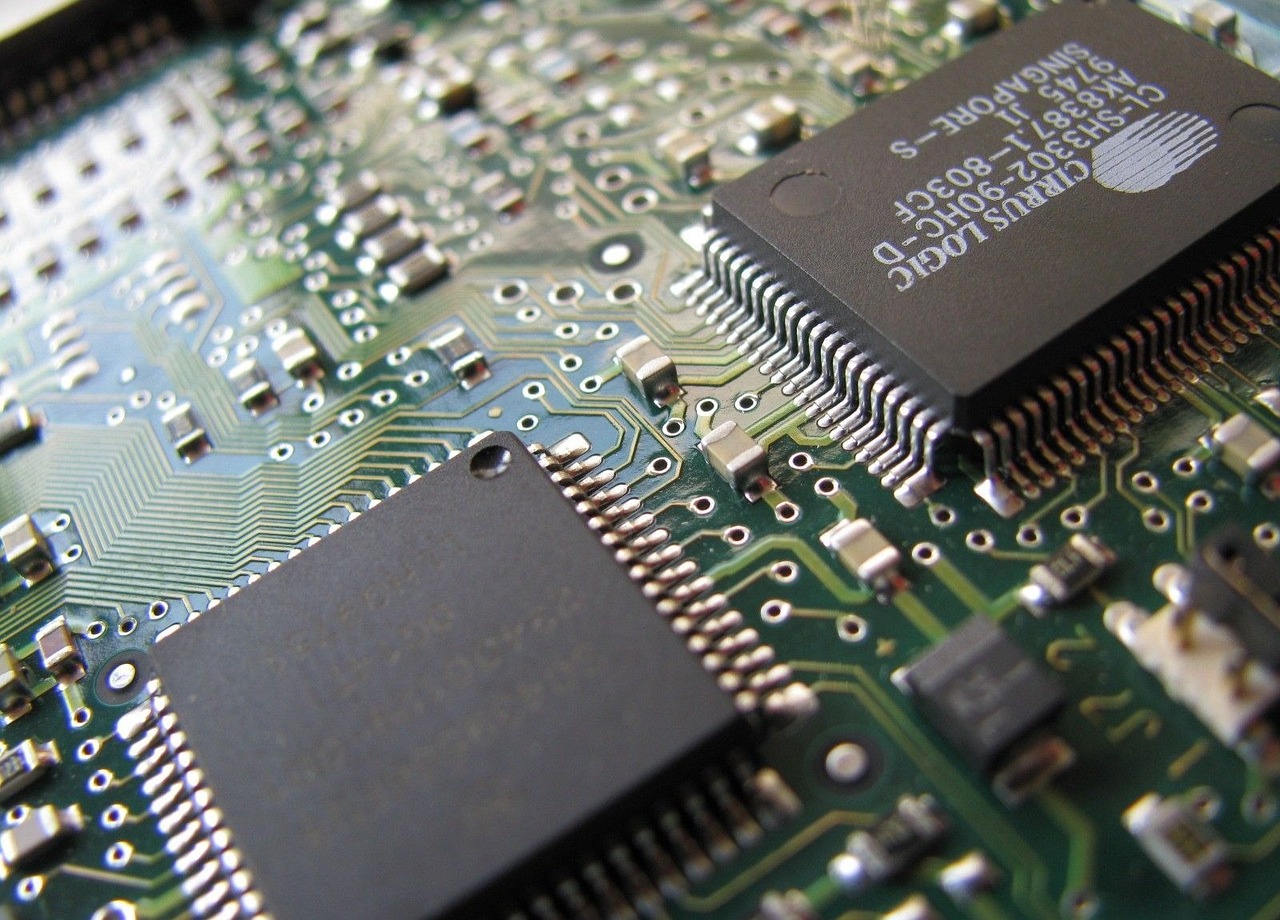

In the following steps, extra silicon is etched off and an extremely complex technique called ion implantation is used to alter the electrical properties of specific parts of the silicon. Another absurdly expensive machine is then used to deposit all manner of required materials to build the circuit like conductors (titanium, aluminum, tungsten etc.) or insulators.

Finally the wafer is tested heavily to make sure that the resulting wafers are nearly flawless.

Cooperation is the Only Answer For Semiconductor Chip Manufacturing

ASML strongly believes that the only way forward in the semiconductor chip business is cooperation, despite the efforts of major powers (namely the US and China) to build their own fully-integrated industries.

If any company knows the industry best, it’s almost certainly ASML as it has a near monopoly on the best lithography machines necessary to make semiconductor chips. Even with a monopoly on these machines, ASML still relies heavily on cooperation between nations.

The Netherlands-based company sources parts for its machines from all over the world. The same is true for the many other complex machines necessary to create a single semiconductor chip.

All of these machine manufacturers like ASML, Tokyo Electron, Lam Research, and Applied Materials need to work closely together to make sure their machines can fit together to create an efficient semiconductor production line.

If these companies didn’t collaborate, the companies actually putting them together like TSMC would be stuck with the tremendously difficult task of integrating them into their production line.

The semiconductor industry is a fascinating paradox of monopolies and close cooperation. There are a few companies that dominate the niche that they operate in like ASML for lithography machines or TSMC for contracted manufacturing of chips at a massive scale. However, these companies are built on cooperation between many different countries that they wouldn’t survive without.

TSMC wouldn’t be able to run its business effectively without ASML machines and ASML wouldn’t be able to build those machines without a massive list of suppliers from around the world.

Nevertheless, the United States, China, and other major powers will continue to try to build their own self-reliant semiconductor industries because of their tremendous importance.

Related Articles:

- Best Tech Stocks to Watch in 2023 – How to Buy Tech Stocks

- The Popularity of TikTok ‘Clothing Haul’ Videos is Now a Vital E-Commerce Metric and Shein’s Are Falling off of a Cliff

- Apple, WhatsApp, Signal, and More Warn UK Bill Meant to Increase Online Safety Would Do the Opposite

What's the Best Crypto to Buy Now?

- B2C Listed the Top Rated Cryptocurrencies for 2023

- Get Early Access to Presales & Private Sales

- KYC Verified & Audited, Public Teams

- Most Voted for Tokens on CoinSniper

- Upcoming Listings on Exchanges, NFT Drops