The world of 3D graphics is a complex field, fueling industries from gaming and film to architecture and engineering. 3D artists and designers use specific techniques and processes like 3D graphic design, rendering, visualization, and animation to bring a vision to life onscreen. But when it comes to taking those 3D images and turning them into physical objects—specifically with 3D printing—the science behind it is called 3D modeling.

3D modeling is much more about logistics than other aspects of 3D design because its output is not a final product like a visual of a 3D object. Instead, it’s a mathematical representation of that object, explaining how that object is put together.

Want to learn more about 3D modeling and how you can rapidly prototype 3D models with the help of 3D printing? Here’s a look at how it works and how it’s used.

What Is 3D Modeling?

3D modeling is equal parts math, geometry, and design. Using specialized software, 3D modeling generates files that are essentially instructions for 3D printers. Like a sculptor, architect, or builder, modeling demonstrates how an object or building will be constructed. If a blueprint is a 2D representation of a building, a model is its 3D representation, giving a mathematical description of the surface of that object.

With programs like Rhinoceros, Blender3D, SketchUp or ZBrush, 3D designers can create files that represent points in space, with plenty of geometry like triangles, polygons, and curves to tie the points together into a three-dimensional object.

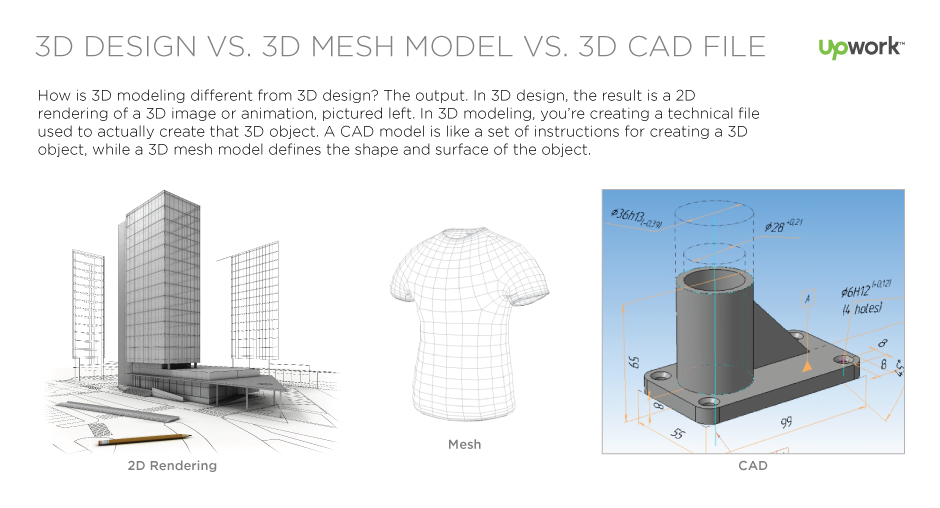

There are two main types of 3D models: computer-aided design (CAD) models, and 3D mesh models, which define the shape and surface. A CAD model can be thought of more like a set of steps for creating the object, which can be tweaked along the way without rewriting the entire file. A mesh is more a representation of how the object’s surface will look, named for its appearance that resembles mesh wrapped around an object.

How Is 3D Modeling Different from 3D Graphics and Rendering?

Essentially, the end result is what makes the two different. In 3D graphics, the result is a 2D rendering of a 3D image or animation, like a photo of an object. In 3D modeling, however, it’s a technical file that can then be used as instructions to create a tangible object.

If you want to describe how an object will be built, you’d use 3D modeling. If you want to see how it will look once it’s built, you’d use 3D rendering.

How Is 3D Modeling Used?

3D modeling has opened up a world of possibilities, giving the ability to prototype 3D objects quickly and affordably. The output you typically get from 3D modeling can be any of the following:

- 3D models printed with a 3D printer

- 2D images created via 3D rendering

- 3D simulations of an object or building

3D models are used in a variety of industries, ranging from art and entertainment like gaming, film, and animation, to engineering, manufacturing, medical devices, architecture, and even geology.

More About 3D Files

Let’s dig a little deeper into the output used to generate these 3D printed models.

STL files are the most common file type created with CAD software. These files take the design and convert it into polygon geometry in a 3D space, and the resulting object will be composed of triangles, vertices, edges, and curves.

An important consideration is file resolution, which will determine things like the quality, surface texture, and detail of your printed object. The lower the resolution of the file, the larger the triangles will be, giving the object a more pixelated look. Setting the resolution of the file in the 3D modeling software you’re using allows you to export higher quality files. High resolution STL files will be larger files, with much more detail—sometimes too much for a printer to process. It’s important to check the printer’s guidelines to ensure you’re exporting the right file size for the equipment.

Bringing 3D Models to Life with 3D Printing

Whether you’re using a 3D printing vendor, renting a machine, or utilizing your own, 3D printing is a far more accessible technology today than ever before. 3D printing allows us to easily create one-off 3D prototypes quickly and inexpensively.

Industrial designers use printers to create and test out prototypes of their designs. With real-time prototyping, they can quickly turn ideas into tangible objects they can test and innovate on much faster and more affordably than with the traditional manufacturing process.

3D printers aren’t far off from 2D home and office printers. In fact, they essentially do the same thing: they create a copy of a computer file, only the result is a tangible 3D object. To bring the STL file to life, a 3D printer typically uses fused deposition modeling (FDM), in which a spool of material (e.g., plastic filament) is melted and transformed into tiny, ribbon-like pieces that are added layer by layer to form a solid object.

Because printers replicate a 3D model exactly by slicing it into layers, your design has to follow certain guidelines or the printer won’t be able to produce it. 3D objects have three axes: an x-, y- and z-axis, indicating height, width, and depth. This means that 3D models must have x-, y-, and z-coordinates.

With different software options, printers, and printing materials to choose from, however, there isn’t a one-size-fits-all answer to getting your 3D model printed. There are lots of things to consider, like what printing material will you use? Do you need the printed object to be flexible or solid? Heavy or lightweight? Do you need interlocking parts? The material you choose can affect aspects of your design (e.g., parts may need to be reinforced or edges smoothed down) and the technology that you use to print with those materials.