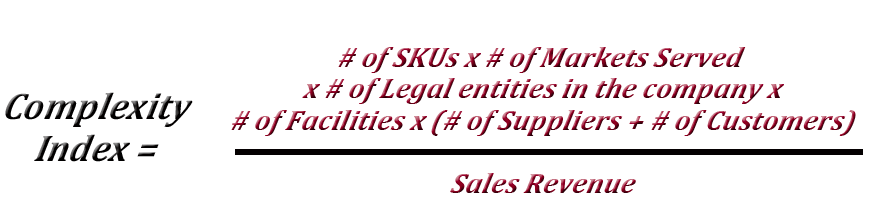

One popular method described here is to determine the complexity level is as follows:

While this approach provides an easy way to come up with a number that reflects a certain level of complexity as related to a company’s size, in reality it may be completely misleading. For instance, I have worked with companies that have a similar number of SKUs yet very different levels of complexity. The difference in many cases is due to the fact that one company has products with different characteristics, requiring multiple supply chain strategies while another has products with very similar characteristics and as a result a lower overall degree of complexity.

The challenge with complexity is that it comes with a “hidden cost” that most companies are not aware of and hence ignore. This cost is in R&D (slower New Product Introduction), Procurement (decrease in economies of scale and hence higher prices), Manufacturing (higher changeover cost and waste) and Supply Chain (worse forecasts, higher inventory and lower service levels). Learning to reduce and manage complexity effectively is one of the most important ways to compete in the market.

But how do you know whether you have a complexity problem?

The best way is to understand the relationship between demand variability, volume, and profit margins by applying a long tail analysis. By employing this analysis together with an understanding of the customer and channel characteristics, you have the opportunity to segment the company’s product offerings and determine how many distinct supply chain strategies are needed. When you do this analysis, you will find many low volume products that have high variability—these products consume a lot of your resources but contribute, in many cases, little to bottom line.

This may seem simple, but in order to do this effectively, you need to have a good understanding of your supply chain costs including inventory in order to create a total landed cost for each product/customer combination. This will require modeling your supply chain in order to calculate these costs. It will also help you understand your cost drivers and define where to set the push/pull boundaries in your supply chain.

Another opportunity for effective complexity management is to include this type of analysis when adding new products or considering end of life for other products as the intersection of product development and supply chain can have a big impact on profitability.

Written by David Simchi-Levi, Chairman of OPS Rules Management Consultants