Many businesses leave finding the right packaging solution to the very last minute.

And the reason is simple.

To your business, your product and your image are most important.

Branding, values, business unique selling points, all these are essential and obviously take priority. So necessities like packaging are left to the last minute.

That’s because packaging, which in many cases is a simple cardboard box, is not exciting. It’s a box. Simple as that, right?

And it’s this approach that usually results in an off-the-shelf, one-size-fits-all form of packaging being implemented and forgotten about.

While this works well for many companies, it can also lead to delays and become a financial drain as your business grows. Typical challenges include cash flow issues and the need for strategic cost optimization; yet again, packaging is overlooked as a potential area for cost savings.

You might be surprised to know that revising that off-the-shelf packaging solution you implemented (and forgot about) has cost-saving possibilities that can make a significant difference.

Value engineering you packaging results in a solution that’s optimised for your specific product while keeping both direct and indirect costs down.

And can look kinda sexy while doing so!

Read on to see more about value-engineered packaging and why your business should implement it.

What exactly is value-engineered packaging?

We can define value-engineered packaging as designing packaging from the ground up with costs, security, and performance in mind.

Both new and existing packaging solutions can be redesigned for both a single product or a wide range of products.

The result is highly customised packaging that leverages economies of scale, without sacrificing quality or performance.

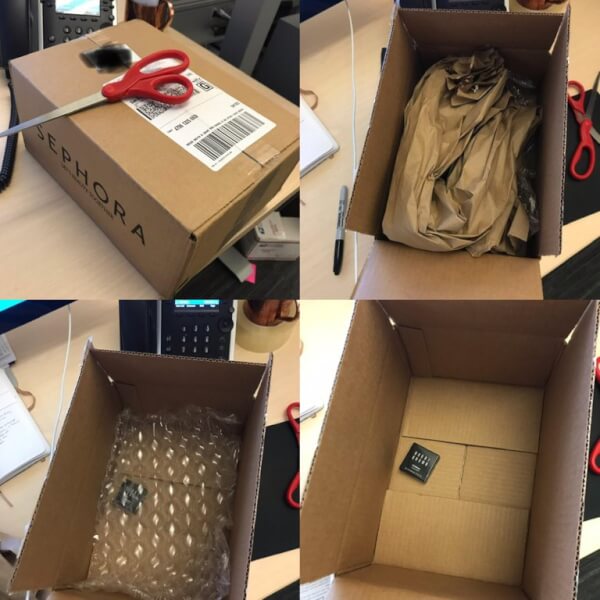

It’s worth noting it’s the economies of scale that are to blame for Amazon, Sephora and other e-commerce giants usingly grotesquely bad (and wasteful) packaging.

Let’s take a look at an example to give you a better idea of good value engineered packaging:

Zozo Elixirs are a women’s cosmetics company, selling online and in-store.

Customers can buy a range of products bundled together, and this bundle is delivered in an elegant, custom-printed corrugated mailer box – a standard, off the shelf packaging solution.

This box also doubles and an ideal delivery method for the brand’s online sales, ideal for shipping internationally.

The use of wood wool ensures that the glass bottles aren’t damaged in transit, and the durable, corrugated cardboard prevents any lazy couriers from damaging the contents when it’s thrown in the back of a delivery van.

This effective, well planned packaging design results in a fantastically branded unboxing experience, and a customer that’s left thinking ‘wow I got a lot more than I thought I would!’

Staying in the cosmetics industry, let’s take a look at Yope Soaps.

Below, you can see Yope’s value-engineered packaging solution:

This is a fine example of value-engineered packaging fulfilling several roles:

- The packaging hugs products tight, ensuring it doesn’t move in transit.

- The carry handle removes the need for retail stores to add a carry bag.

- The thinner, lighter cardboard saves on shipping and storage costs.

Furthermore, Yope’s solution uses less material to packaging a higher volume of product in comparison to that of Zozo.

And there’s a reason for this difference – Zozo is a smaller operation with only several product lines. In contrast, Yope has hundreds of SKUs to manage, dozens of sales channels and multiple distribution methods.

But this is also the reason why Yope has value-engineered their packaging – to ensure that the most amount of SKUs can be used in the lowest number of packaging products.

Value engineered packaging is cost-effective.

At the end of the day, you don’t really know if you’re paying too much for your packaging.

All you know is that the price you’re paying for your packaging supplies is competitive in comparison to all other providers on the market.

Combine this with the fact that more and more consumers expect eco-packaging, how can you be sure if your packaging supplies really are sustainable?

And this is the standard approach to many consumables and supplies for your business.

As long as you’re getting a good product for a good price and it does what it says, it’s all good, right?

Well, not always.

An engineering-first approach to packaging (rather than value-first), can help you cut down expenditure and find even more savings.

Is your packaging made from the most optimal material for your purpose?

Well, you don’t know.

All you know is that your packaging is made from the most optimal material for the factory to produce.

Cost savings in both the short term and the long term by going engineering-first rather than value-first.

A company selling, for example, crockery, may opt for a large, double-walled cardboard box. This type of box supports the weight of the plates, while tightly packed void filler prevents the plates hitting each other, as well as the side of the packaging.

It’s safe, and there’s very little chance of the fragile content being broken in transit. Both the box and the void filler are readily available packaging products.

However, a single-walled box with a custom made insert uses less material and provides extra security.

A custom insert ensures that the product doesn’t move at all while in transit. This eliminates the need for wood wool or other packaging fillers, as well as the second layer of corrugated cardboard.

The best person to design an insert, and help create your value-engineered packaging is a packaging engineer.

What is a packaging engineer?

A packaging engineer is an experienced individual, familiar with material technology, physics, design, and manufacturing.

Whether designing from scratch or improving your existing packaging, a packaging engineer looks at:

- Materials

- Dimensions

- Your product to be packaged

- The packaging construction process

- The number of units you need

- Transport and storage requirements

All these aspects listed above are things that off-the-shelf packaging solutions assume.

Your packaging engineer is the one responsible for creating packaging that doesn’t assume these things but is rather tailor-made with these considerations in mind.

Excessive weight in the attempt to add security is another problem that your brand will face by using standard, off the shelf packaging.

This over-engineering is the most effective way to create a packaging product that does as many roles as possible. Still, it ultimately costs you money in storage and delivery fees.

A packaging engineer easily identifies both over-designed and over-engineered packaging solutions. Effective material substitution is another way that a packaging engineer can keep more money in your back pocket in the long run.

Carbon footprints & packaging

78% of consumers now say that they’d change their mind about purchasing a product if the packaging isn’t environmentally friendly.

As a result, business owners are now thinking about the environmental impact of the packaging products that implement into their supply chain. They must also consider where this packaging comes from and where it ends up.

So, how can value-engineered packaging lower help you appeal to the eco-conscious consumer?

An experienced packaging engineer can help you work sustainability into your packaging design for several reasons:

- Sustainable packaging helps lower carbon emissions and pollution

- Sustainable packaging can help a brand appeal to a broader demographic

- Simply using less material is the best thing your brand can do to lower its consumption of raw materials.

90% of consumers will avoid a brand if it’s not transparent.

So when your brand can say, and prove, that your packaging is made from recycled pulp or sustainably sourced plant fibre, you’re putting that transparency, and ultimately trust, into your brand.

Packaging engineers know that, while vegan inks are derived from plants, they can have as little as 7% plant oil in them, with the rest being unsustainable, mineral-based ingredients. Furthermore, vegan inks don’t always create as vibrant print as other forms of ink.

An experienced packaging engineer knows this and uses the most appropriate printing techniques to ensure that, if vegan ink is used, the printed design is as vivid as it can be.

Rationalisation

Packaging rationalisation is the process of creating the smallest amount of packaging options for the most amount of product SKUs.

It does, however, require the development of a packaging MPV or prototype for each product. Next, these prototypes are amalgamated into one packaging solution.

This is why packaging rationalisation is a time-consuming process, but incredibly powerful on a large scale.

However, the results far out weight the initial costs:

- Reduction of ongoing packaging costs

- Fewer packaging product SKUs

- Packaging supplies take up less space on warehouse shelves

- Savings can be made by buying high volumes of packaging

- More efficient inventory management

Packaging rationalisation is aided by demand forecasting, which assesses how fast your products move off your shelves.

By putting both fast and slow-moving lines in the same packaging design, you’ll eliminate the need to keep both deadstock and its corresponding packaging in your inventory for an extended period.

Indirect savings

Warehouse optimisation and storage space are a few ways that value-engineered packaging can have indirect savings for your business. Packaging supplies that take up as little space in your warehouse make it easier to manage your daily operations and fulfilment processes.

A packaging engineer takes into consideration the size of a pallet, and how your unassembled packaging fits onto a pallet or other material handling platform.

- Are you ok with the flat packaging hanging over the side of the pallet?

- Would you rather the packaging design is separated into multiple, smaller pieces to fit on one pallet?

- Is your packaging assembled by machine or by hand?

Your brand’s responses to these questions affect the design of your packaging as to cater to your warehousing and fulfilment process as best as possible.

Other indirect savings are seen in the form of lowered shipping costs.

Weight and space optimisation means that your packaging is as light as it can be without compromising on security or performance.

This is mostly done by material substitution. For example, does your cardboard tube need a triple-ply end piece, or will a pressed aluminium cap suffice?

Whether you pay your shipping charges based on weight, size or both, an engineered packaging solution keeps shipping costs down, and more money in your pocket.

Value-engineered packaging – is it for you?

There’s so much more to packaging than a simple box. Overlooking your current packaging supplies as a place to save money is like shooting yourself in the foot. It’s because your packaging is so often forgotten about, that it should be the first place you look to save money.

Value engineered packaging and working closely with a packaging engineer changes all this.

Through rigorous testing and prototyping, the best packaging solution for your brand can be found and implemented.

The result is not only a better-looking packaging solution but more money in your back pocket.