With inflation and increased competition, it is vital to reduce the cost of the final product while maintaining quality. Practically speaking, it’s impossible to cut the cost involved in core technical and non-technical activities. The only thing left to experiment is Supply Chain.

As an entrepreneur or CEO of a company, you should always look for total transportation costs in the final product cost sheet. That’s the area where the focus should be shifted to reduce overall cost and increase the margin. Normally, the supply chain involves processes related to product sourcing and delivery. Supply chain management ensures effective management of product/services distribution with reduced cost and higher efficiency. It involves procurement, logistics, operations, and delivery.

For successful management, it is essential to have an optimum flow of products/services and you need to make sure that the correct product reaches the user at the right time and the right location as per his convenience.

Then,

What is Global Supply Chain Management?

Global supply chain management can be defined as an inter-nation transfer of raw materials, finished goods, and services while reducing final cost and ensuring optimum product quality. The difference between normal supply chain and global one is not only related to import/export but it is more connected to a strategic partnership with suppliers, warehouses, and logistics-related firms of other countries to make the supply chain as smooth as possible. While opting for global supply chain management, you need to follow all the global trade compliances set by a particular host country and WTO (World Trade Organization).

Importance of Technology in Global Supply Chain

The importance of technology in any field is paramount. Managing a supply chain is a complex task and the number of manual errors will be quite high. In such a situation, integration of technologies like AI (Artificial Intelligence), Big Data, IoT (Internet Of Things) can transform your logistics and operations.

By integrating AI to the supply chain, companies will be gaining $1.3tr to $2tr a year in economic value – Mckinsey & Company. According to PWC, the contribution of AI will be $15.7 tr to the global economy by 2030.

Considering this importance, here are the handpicked ways in which AI can integrate and transform the global supply chain management.

1. Leveraging AI in Procurement

The procurement decision is the most critical in the entire supply chain. It involves finding different suppliers, marking their locations, checking raw materials quality, and cost negotiations before setting up the supply chain. Raw material procurement is considered to be the fundamental step of global supply chain management. Within that, you can import products from other countries and integrate it into your final product to reduce the production cost while ensuring a minimum transportation cost. This process is called outsourcing.

But these decisions can be affected by environmental, political, and financial factors and the final cost will be changed accordingly. This situation calls for the intervention of Artificial Intelligence (AI).

With AI-based models, you can evaluate different suppliers from historic data and provide the ratings. Based on ratings, you can provide them a credit score and finalize the decision on whether to buy it from local or global suppliers or outsourcing some work.

2. Warehouse Management With AI-Enabled Software

Automation and AI-enabled software make it easy to manage the warehouse. These technologies will visually check finished goods for any damage and reduce the manual quality check cost.

Also, automation will make sure to enable the smooth flow of products within the warehouse. Robotics technology is here to assist in product sorting and packaging in different sizes.

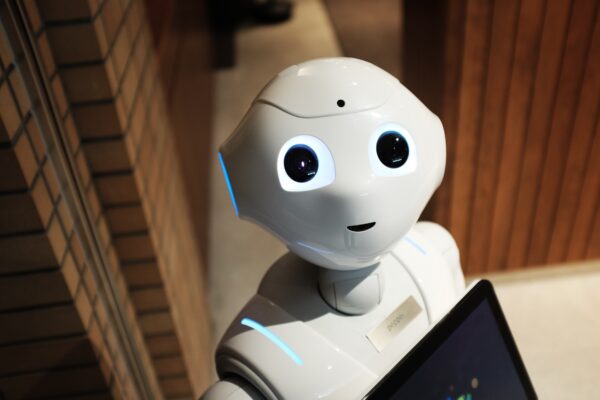

3. Redefining Customer Support With AI-Powered Chatbot

80% of customer communication can be handled by a chatbot – Accenture

A chatbot is the backbone of modern-day customer communication. Especially, it’s 24*7 availability makes it mandatory to use in query resolution. This feature makes it desirable for shipping companies to implement on the website.

Nowadays, all the shipment related queries are handled by a chatbot. It works based on pre-programmed questions set up within the system. When it faces complex questions, it will work as a bridge between your customer and shipment company.

For example, DHL made a partnership with Amazon Alexa in providing faster resolution of support queries. Users can ask directly via Amazon smart speakers about their parcel’s delivery status which reduces their time in seeking a solution.

4. Boosting Supply Chain Productivity With AI-Based Insights

When AI integrates with the supply chain, it is assumed to have an impact only on the overall cost. More than that, AI applications can analyze the whole supply chain by finding bottlenecks within each and every process.

Supervised, unsupervised, and reinforcement learning make AI more powerful to boost the productivity of the supply chain with overall performance optimization.

Final Words

With too much investment in technologies, we often forget the most important element in the whole cycle – Human.

Human efforts are important in 2 parts of successful technology integration within the global supply chain.

- Finding critical points for integrating AI

- Finding newer technologies for further improvement in the supply chain

One practical situation can be chatbot’s inability to interpret complex user queries. This is the time where the support agent needs to intervene to listen and understand the user’s problems and assist him with added value. Equal contribution of humans and technology is required to optimize and manage the global supply chain.