What Is Vertical Integration?

Vertical integration is a strategy where a company takes ownership of multiple stages of its supply chain, production, and distribution process. By bringing more steps in-house, a vertically integrated company can streamline operations and reduce costs by cutting out the middle men.

How Does Vertical Integration Work?

There are a few ways companies can become vertically integrated:

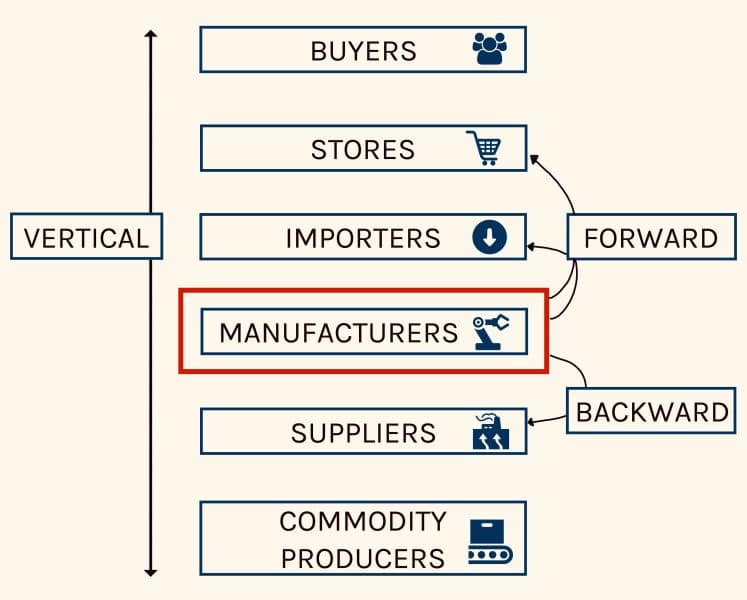

- Backward Integration involves taking ownership of suppliers that provide inputs for production. An auto manufacturer buying a steel company to produce its own auto bodies is an example of backwards integration.

- Forward Integration involves taking ownership of distribution and retailers to get closer to customers. A food manufacturer acquiring a trucking company and supermarket chains to transport and sell products directly is an example of forward integration.

- Balanced Integration involves combining backward and forward integration to control more of the supply chain. For example, a clothing company owning textile mills, factories, and retail stores.

The core goal is to gain more control and visibility across the value chain from raw materials to finished products sold to end consumers.

Examples of Vertical Integration

Notable examples include:

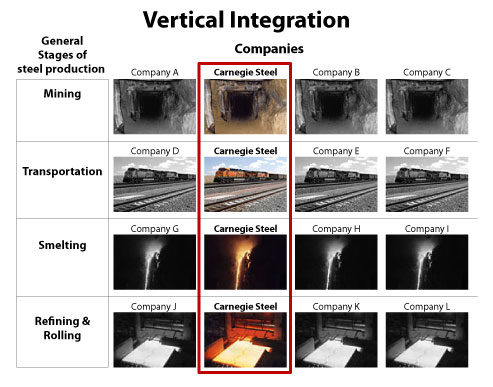

- Andrew Carnegie’s US Steel was perhaps the most famous example where he vertically integrated every major step involved in steel production to drive costs down tremendously and force his competition out of business.

- Oil companies like ExxonMobil explore, extract, refine, and sell final petroleum products directly to consumers at its company-owned gas stations.

- Boeing acquiring several key aerospace component suppliers to produce more aircraft parts in-house.

- Amazon purchasing Whole Foods to sell private label grocery products directly in Whole Foods stores.