Boeing has been swept into turbulent skies this year as its commitment to safety and engineering excellence has been questioned by authorities, customers, and insiders due to a series of incidents that have plagued its reputation.

The large number of internal claims stating that Boeing’s senior management has been neglecting the company’s quality assurance procedures while prioritizing cost-cutting measures is mounting, and this has prompted regulators to take a closer look at what the company is doing to make sure that the skies are safe.

Boeing’s miserable year started with a door plug panel flying off of a Boeing 737 Max 9 mid-flight. Although no one was killed, it caused the plane’s decompression and resulted in the loss of valuable passenger belongings.

“We are very, very fortunate here that this didn’t end up in something more tragic,” commented the Chair of the National Transportation Safety Board, Jennifer Homendy, who added that the reason why this event did not end in fatal casualties was that seats 26A and 26B were unoccupied during the flight.

The Federal Aviation Administration (FAA) issued an order to ground all Boeing 737 Max 9 for multiple weeks, dealing yet another blow to both Boeing’s reputation and finances but enforcing a reasonable action considering the severity of the situation.

Whistleblower Allegations and Production Line Audits

Days after the FAA enforced the Max’s grounding, an investigation was opened into Boeing’s practices and manufacturing processes to identify the cause of the issue and make sure that the company is adopting the best practices to produce its aircraft.

Both insiders from a Boeing supplier called Spirit AeroSystems and internal inspections from United Airlines emphasize that they have found multiple issues within the Max 9 models delivered by Boeing that hint at quality control issues.

However, on 16 January, an anonymous Boeing insider stepped up to blame Boeing for ignoring the existence of issues in its assembly lines that resulted in incidents like the one involving the Alaska Airlines aircraft.

The allegations from this whistleblower added fuel to the already growing concerns about Boeing’s quality control practices and coincided with previous claims from former employees and aviation safety advocates about a concerning shift in the company’s priorities.

Also read: History of Boeing: Conquering the Skies Before Scandal Hit

Ed Pierson, a former Boeing executive and current executive director of the Foundation for Aviation Safety, told CNN: “Leadership is more concerned with getting the planes out the door than quality.”

“The company has gutted quality control so they can produce more airplanes… The employees are completely overwhelmed. Everybody is focused on the Max 9, and rightfully so. That incident should never have happened. But there are issues on other planes. It has become a recipe for disaster,” he said, referring to the source of the issue being related to the company’s culture rather than being an isolated incident.

On 12 January, in the midst of this mounting public outcry over Boeing’s practices, the FAA announced that it would commence a thorough audit of the company’s production processes to ensure that it is complying with the industry’s best practices.

Just 12 days later, the 737 Max is cleared to take off by the FAA once again after a “thorough inspection and maintenance process”. However, the agency forbids the company from scaling its assembly line for this aircraft model until it satisfies the regulator’s calls for augmented quality controls.

Boeing’s Quality Control Issues Are Nothing New

This is hardly the first time Boeing has been in the eye of the storm as the company has faced mounting scrutiny over its manufacturing processes and especially its quality control in previous years after the two deadly crashes involving the 737 Max predecessor in 2018 and 2019.

Back then, the resulting investigations pointed at design flaws in the aircraft flight control systems, suggesting that Boeing’s poor quality control was a major contributor to the tragedies.

“In the light most favorable to Boeing, the first crash was an accident, the second crash is a crime. They gambled with people’s lives, and the people lost,” commented Robert Clifford, who represented the families of the second incident involving a crash in Ethiopia.

“They gambled with people’s lives, and the people lost,” referring to the company’s negligence as they were aware of the issues that affected these planes but failed to take prompt action that could have avoided the tragic incident.

Boeing ultimately admitted being partially responsible for the two crashes and agreed to pay compensatory damages to the victims’ families and a $2.5 billion fine to settle charges of defrauding the FAA during the 737 Max’s initial approval process. The families are baffled that no criminal charges were filed, though that may change as Boeing allegedly broke its agreement with the DOJ that protected it from criminal liability.

Boeing’s Corporate Culture Shifted from Quality Assurance to Profit Growth

Aviation experts claim that Boeing’s woes hint at a fundamental shift in the company’s culture that has been occurring during the past two decades as the senior management has focused primarily on growing profits than assuring the quality of its products.

Following the company’s merger with McDonnell Douglas in 1997, Boeing’s top ranks were filled up primarily by executives with no aviation background who started to prioritize the firm’s financial health over quality controls and safety protocols.

Also read: New Whistleblower Crisis Hits Boeing as Stock Continues to Underperform

“Boeing had a reputation before the merger of a company where engineers were high church,” said Ron Epstein, an aerospace analyst at Bank of America. However, Epstein claims that shortly, after the merger concluded, “everything had to be cost-justified.”

Boeing’s decisions to outsource more production to suppliers, spin-off divisions like Spirit AeroSystems, and establish non-union facilities in pursuit of cost savings have all been cited as contributing factors to the company’s current misfortunes.

Despite these efforts to prioritize the financial side of the business, the company has been delivering anything but a profitable outcome as net losses in the past five years near $30 billion.

In contrast, Airbus, Boeing’s main rival, is about to report a net profit exceeding $4 billion in 2023 alone.

Richard Aboulafia, managing director at AeroDynamic Advisory, warned: “You’re looking at a management team whose idea of acknowledging the problem is to readjust the cash flow numbers for next year.”

“It’s a very weird industry. It has high barriers to entry and only two players. You can get away with nonsense like this,” he added.

FAA Audit Reveals Quality Control Issues, Boeing Top Exec Departs

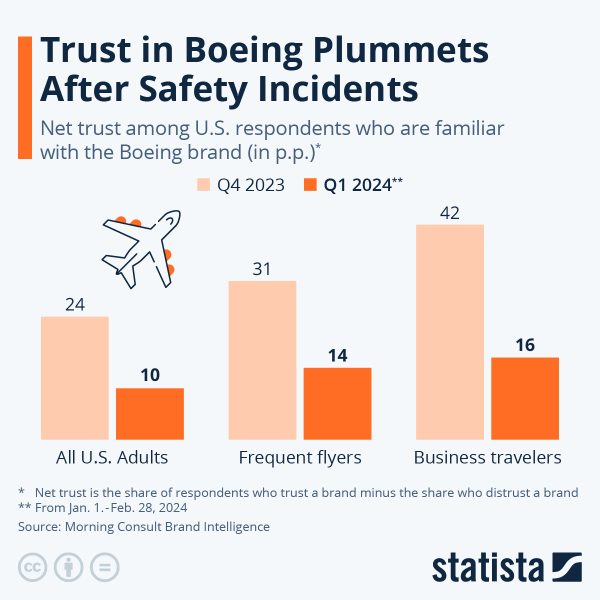

In March, the FAA revealed its findings after months of auditing the company’s manufacturing procedures. Up to this point, customers have grown more reluctant to fly on a Boeing aircraft due to bad press and the Alaska Airlines incident – a situation that had been affecting the demand for tickets for commercial airlines.

After a 90-day period extended by the agency to prompt the company to improve its quality control processes, the regulator came out with the results of its audit, which included problems in numerous areas such as parts handling, storage, and manufacturing processes.

During this period, the head of the 737 Max program, Ed Clark, is ousted and replaced by Katie Ringgold. The NTSB’s initial findings concerning the Alaska Airlines incident claim that four bolts were missing from the door that blew up mid-air.

The FAA also said that, during its audit, they saw evidence of a worrying disconnect between “Boeing’s senior management and other members of the organization on safety culture.”

Meanwhile, the NTSB blasts Boeing for not providing the information they required on the employees who were responsible for putting the bolts on the door that blew up during the Alaska Airlines flight.

Finally, in a rather shady turn of events, a former Boeing employee who was scheduled to give his testimony in court was found dead in early March. The initial reports pointed at a self-inflicted gun shot but the situation does anything but good to the company’s reputation.

A Hearing is Scheduled for August to Further Investigate the Door Plug Incident

As Boeing grapples with the fallout from these latest incidents and investigations, the company faces an uphill battle to regain the trust of regulators, customers, and the general public who flies in its planes.

In a statement this year, FAA Administrator Mike Whitaker emphasized, “Boeing must commit to real and profound improvements. Boeing must take a fresh look at every aspect of their quality control process and ensure that safety is the company’s guiding principle.”

Meanwhile, Stan Deal, the CEO of Boeing’s commercial airplane unit, acknowledged the company’s failings, stating, “Over the last century, the people of Boeing have faced and overcome significant challenges. This is one of those times. We have to be better. We have to deliver perfect airplanes each and every time.”

A hearing is scheduled to take place in early August this year to further investigate the Alaska Airlines incident and how liable the company is for this flaw that could have resulted in the death of several passengers and crew members who were on board.