When PLM meets machine learning, Best-in-Class organizations “swipe right” to convert potential to productivity, resulting in better user experiences and better products. In a nutshell, machine learning definitely spices up the staid and steady PLM value proposition.

With the rise of big data, machine learning is creating new methods to handle all aspects of manufacturing, including customer interaction, design, supply chain, and product lifecycle management. The mix of big data and affordable, powerful computing systems has made machine learning usable in real-world situations, leading to positive changes in the product development process.

Today’s Best-in-Class companies are embracing a new era of digital transformation in product lifecycle management (PLM). Among their quiver of Fourth Industrial Revolution tools is machine learning, which they are almost 2x more likely to implement than All Others (Figure 1).

Figure 1: The Best-in-Class Implement Machine Learning at Higher Levels

PLM systems gather a large amount of data, including product details like user behavior, seasonality, materials, specifications, and more. Now and in the future, the strength of PLM data will be utilized through machine learning models to provide more insights into the product lifecycle. Here are some potential use cases that are either available now or will be soon, through built-in PLM features or integration into the PLM solution:

- Increasing Design Productivity. Machine learning can be harnessed in PLM to create adaptive interfaces that increase user design productivity. This product feature predicts next steps and updates the user interface accordingly, helping users increase productivity. The ability to automatically adapt the user interface to meet the needs of different types of users across multiple departments can result in a higher-quality design experience.

- Reducing Supply Chain Delays. Faster time-to-market is always important, and a PLM solution that uses machine learning can quickly recommend alternative suppliers at competing costs, in a geographical location that won’t increase costs or cause further delays. In addition, these automated recommendations can factor in historical supplier performance and reputation to ensure that quality and compliance standards are met and the best performers’ parts are chosen.

- Better Decision Management. Machine learning is increasingly being leveraged in the product design process to provide a competitive advantage. ML can be used to deliver valuable business insights more quickly and efficiently, and it has the power to process, analyze, and learn from large volumes of data. When provided access to historic sales data and unfiltered customer feedback, machine learning insight can enable product designers to utilize insights to improve future product lines. Similar to the benefits of virtual prototyping, machine learning has the potential to determine which of millions of possible combinations of product attributes will results in higher gross margins.

Digitalization of PLM is just beginning, but already the potential machine learning use cases for PLM look very exciting. In PLM, Aberdeen sees the rise of a virtuous circle between manufacturing data and the ability to harness it via machine learning. Simply put:

- Machine learning-ingested data enables improved insights.

- Improved insights result in better products.

- These great products attract even more users.

The Numbers: Manufacturer Buyer Intent in Machine Learning and PLM

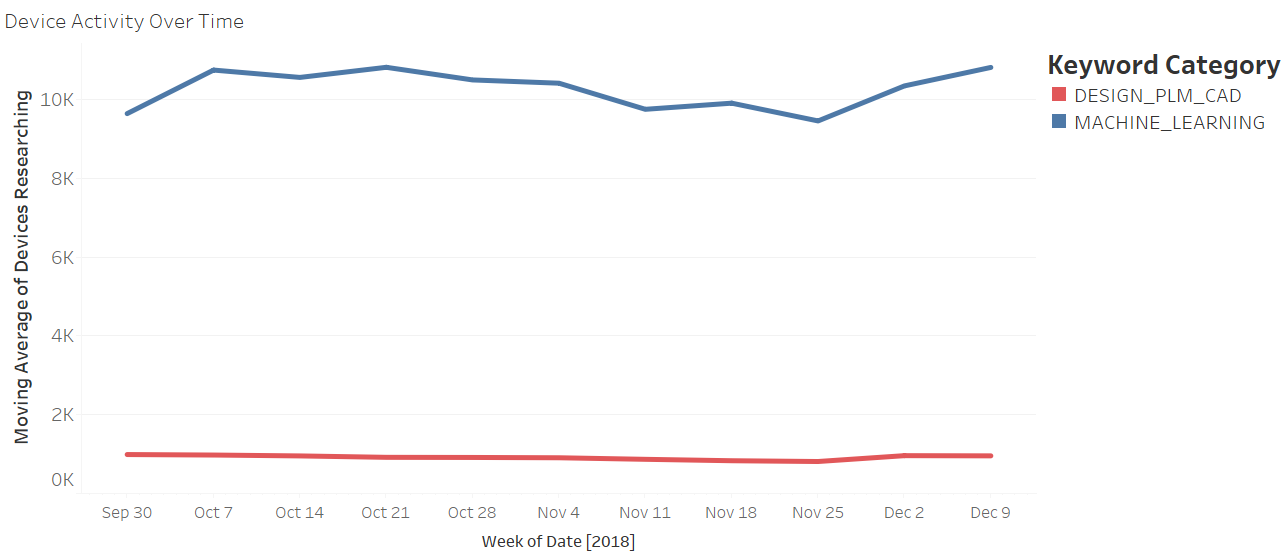

Aberdeen tracks buyer behavior and content consumption across millions of websites to connect web-based search activity to discernible purchase intent signals. In addition to those intent signals, this data also reveals macro-level trends in the relative interest level for AI technology. To this end, Aberdeen maintains several industry-focused indices that demonstrate sector-level fluctuation in research activity across hundreds of technology categories. One such index contains thousands of organizations in the manufacturing sector.

If we take a six-month view of aggregate activity for this index, focused on technology categories related to manufacturing analytics and big data, the findings reveal a discernible bias toward more sophisticated and cutting-edge technologies (Figure 2).

Figure 2: Machine Learning and PLM Buyer Intent in Manufacturing

In aggregate, this Manufacturing index shows a sustained buyer intent signal in machine learning and steady interest in PLM: Manufacturing providers are looking to bring new and sophisticated analyses to the abundant data they maintain. A major push in the manufacturing is the strong desire to convert this data into focused predictive insights. The results show that machine learning and PLM are a means to accomplish that goal.

Aberdeen’s intent data provides a macro-level view of how Manufacturing and large groups of companies are consuming content, and where their interests lie. However, this data also provides a more granular, company-level view, down to the device ID. This provides unprecedented clarity into how specific organizations are consuming content, and where they might be making near-term investments.

Do you know which specific companies are currently in-market to buy your product?

Wouldn’t it be easier to sell to them if you already knew who they were, what they thought of you, and what they thought of your competitors?

Good news – It is now possible to know this, with up to 91% accuracy. Check out Aberdeen’s comprehensive report Demystifying B2B Purchase Intent Data to learn more.